End-of-line inspection

End-of-line inspection important to ensure the products of each production line meets the required quality level before they are transferred to the next lines. End-of-line inspections also need to provide feedbacks to the production line managers and inline inspectors to have better and timely control of the quality

Prospective users:

Quality control function and end-of-line quality inspectors

This practice can be applied to all kinds of factories.

ProblemS addressed

- Low quality and high defect rate of semi-final products or line products

Process

This process includes assigning end-of-line inspectors, providing them with inspection instructions and sample of good or bad semi-final products, conducting inspection of semi-products at end of each production line and providing feedbacks for production and inline inspection.

Steps in implementation

- Arrange the end-line inspection workstation. This inspection workstation should be at the end of the production line.

- The QC work-station should be logically arranged which contributes largely to the improvement of work quality and productivity. QC workstation should have a large table and a white board which provides sufficient space for placing products for quality control as well as posting any aids to the end-line inspection.

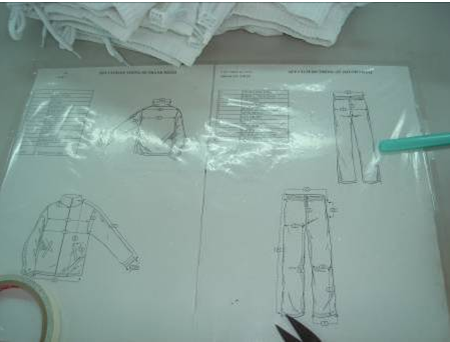

- There should be specification sheets- more description of specification sheets required- or even another GPG posted of the wall or boards.

- Any tools necessary for quality inspection or measurement should be provided. Sufficient light is essential for the good work of end-line inspectors.

- Assign end-line inspectors. End-line inspectors should be trained in conducting end-line inspection and providing feedbacks to in-line inspection and production.

- Ensure that all staff can identify quality control staff by having a distinguishing uniform or hat.

- Provide end-line inspectors with end-line inspection report forms. (See GPG #3 – Using Checklists for quality control)

- Display specification sheets (See GPG #10 – Specification Sheets) and at end-line inspection workstations.

- QC instruction should be clear and put in working place of QC for easy reference. – More description of QC instructions

- In addition to QC instruction, create end-line inspection points list. This list of end-line inspection points should be made available at the end-line inspection workstation.

- Sample of defect is put in working place where inspectors can easily see and access.

- The trolleys should be logically designed at the ironing and QC phase, which help to avoid wrinkles on the products; reduce working step and at the same time keep the workshop tidier.

- End-line inspectors check products for defects. Once any errors detected, this is marked by a defect ticket attached to the products and returned to the line for quick fix.

- Use end-line inspection reports or checklists to record the defects

- Summarize the major defects for reporting and discussion for improvement.

- Provide feedback about major defects to inline inspectors, supervisors and workers to help them understand how to prevent defects.

Resources required

- List of key end-line inspection points

- Sample defects available at the QC station

- End-line inspection checklists or report forms available to inspectors

- Involvement of end-line inspection staff

Challenges and pitfalls

- Time consuming to fix the defects

- May overlap with inline inspection

Positive impact

- Lower level of pre-delivery defects

- Feedbacks to enhance in-line inspections and productions

- Data for analysis to enhance quality

Indicators for monitoring

- End-line inspectors assigned

- End-line inspection is conducted in all working shifts

- End-line inspection reports filled with all observed defects

- All products went out the line are confirmed with quality standards

Funding for the Factory Improvement Programme is provided by the Swiss State Secretariat for Economic Affairs and the United States Department of Labor.